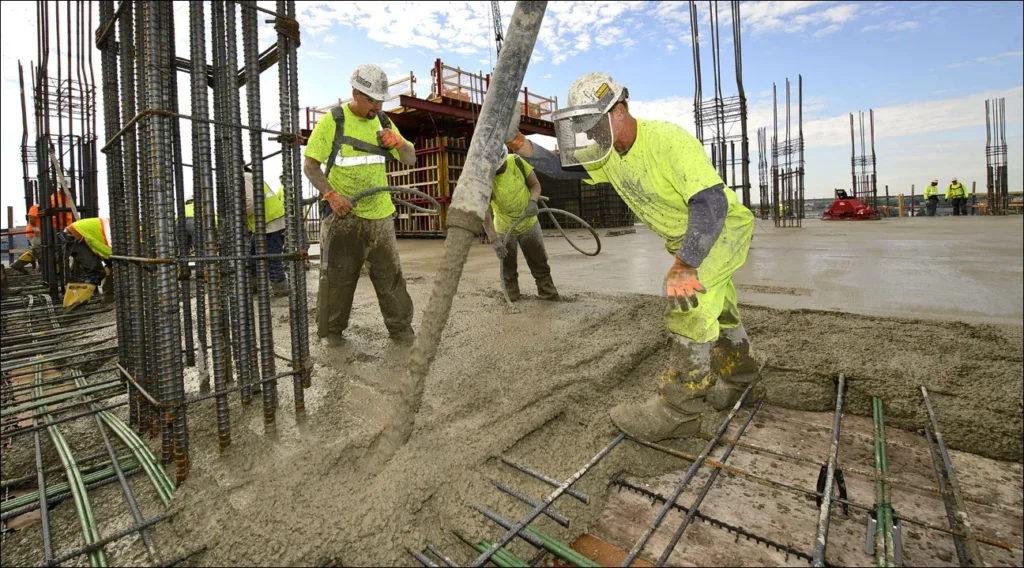

Each member of the Concrete Crew Denton TX plays a specific role and contributes to the overall efficiency, safety, and quality of the project.

Here are the key roles and responsibilities of a concrete crew:

- Concrete Foreman/Supervisor:

- The concrete foreman or supervisor is responsible for overseeing all aspects of the concrete construction project. Their duties include:

- Planning and scheduling concrete pours to ensure timely completion of the project.

- Coordinating with project managers, contractors, and other stakeholders to communicate project requirements and objectives.

- Managing the concrete crew, assigning tasks, and providing guidance and direction to ensure work is performed efficiently and safely.

- Monitoring quality control and ensuring compliance with project specifications, codes, and regulations.

- Conducting safety meetings, toolbox talks, and training sessions to promote a culture of safety among crew members.

- The concrete foreman or supervisor is responsible for overseeing all aspects of the concrete construction project. Their duties include:

- Concrete Finishers:

- Concrete finishers are skilled tradespeople responsible for finishing and surfacing concrete structures. Their duties include:

- Smoothing and leveling freshly poured concrete using hand tools such as trowels, floats, and screeds.

- Creating desired surface textures and finishes, such as smooth, broom, or stamped finishes, to meet project requirements.

- Applying curing compounds, sealers, or protective coatings to enhance the appearance and durability of the concrete surface.

- Repairing and patching imperfections or defects in the concrete, such as cracks, voids, or spalls, using appropriate repair materials and techniques.

- Concrete finishers are skilled tradespeople responsible for finishing and surfacing concrete structures. Their duties include:

- Concrete Laborers:

- Concrete laborers provide essential support to the concrete crew by performing various tasks to prepare, place, and finish concrete. Their duties include:

- Assisting with the setup and installation of formwork, reinforcing steel, and other construction materials.

- Mixing, transporting, and pouring concrete using concrete trucks, pumps, or wheelbarrows.

- Assisting finishers with screeding, floating, and troweling operations to achieve smooth and uniform concrete surfaces.

- Cleaning and maintaining tools, equipment, and work areas to ensure a safe and organized job site.

- Concrete laborers provide essential support to the concrete crew by performing various tasks to prepare, place, and finish concrete. Their duties include:

- Concrete Pump Operators:

- Concrete pump operators are responsible for operating and maintaining concrete pumping equipment used to transport and place concrete at construction sites. Their duties include:

- Setting up and positioning concrete pumps to reach desired locations for concrete placement, such as elevated decks or inaccessible areas.

- Operating pumps to control the flow and pressure of concrete during placement, ensuring proper distribution and consolidation.

- Monitoring pump performance and troubleshooting equipment issues to prevent delays or downtime.

- Conducting routine maintenance and inspections of pumps, hoses, and accessories to ensure safe and reliable operation.

- Concrete pump operators are responsible for operating and maintaining concrete pumping equipment used to transport and place concrete at construction sites. Their duties include:

- Concrete Formwork Carpenters:

- Concrete formwork carpenters specialize in building and installing formwork, also known as molds or shuttering, used to contain and shape concrete during pouring. Their duties include:

- Reading and interpreting construction drawings and blueprints to determine formwork dimensions, layouts, and specifications.

- Constructing formwork systems using lumber, plywood, or prefabricated materials, ensuring accuracy, stability, and alignment.

- Installing form ties, braces, and supports to secure formwork in place and withstand the pressure of freshly poured concrete.

- Stripping, dismantling, and removing formwork after concrete has cured, salvaging reusable materials and ensuring proper disposal of waste.

- Concrete formwork carpenters specialize in building and installing formwork, also known as molds or shuttering, used to contain and shape concrete during pouring. Their duties include:

- Concrete Pump Mechanics:

- Concrete pump mechanics specialize in maintaining, repairing, and servicing concrete pumping equipment to ensure reliable performance and safety. Their duties include:

- Diagnosing mechanical, hydraulic, and electrical issues affecting concrete pumps and associated components.

- Performing preventive maintenance tasks such as lubrication, fluid checks, and filter replacements to prevent equipment breakdowns.

- Repairing or replacing damaged or worn parts, components, and systems to restore pump functionality and performance.

- Conducting safety inspections and tests on pumps, hoses, and accessories to verify compliance with regulatory standards and manufacturer specifications.

- Concrete pump mechanics specialize in maintaining, repairing, and servicing concrete pumping equipment to ensure reliable performance and safety. Their duties include:

- Concrete Testing Technicians:

- Concrete testing technicians are responsible for performing quality control tests and inspections on concrete materials and structures to verify compliance with project specifications and industry standards. Their duties include:

- Collecting samples of freshly mixed concrete for testing and analysis, including slump tests, air content tests, and temperature measurements.

- Conducting laboratory tests on concrete samples to assess properties such as compressive strength, density, and durability.

- Performing non-destructive tests such as ultrasonic testing or rebound hammer testing to evaluate the integrity and condition of concrete structures.

- Documenting test results, preparing reports, and communicating findings to project stakeholders to ensure proper quality assurance and quality control.

- Concrete testing technicians are responsible for performing quality control tests and inspections on concrete materials and structures to verify compliance with project specifications and industry standards. Their duties include:

- Concrete Equipment Operators:

- Concrete equipment operators are responsible for operating and maneuvering heavy equipment used in concrete construction, such as concrete trucks, mixers, and batch plants. Their duties include:

- Operating controls to load, mix, transport, and discharge concrete materials safely and efficiently.

- Maneuvering equipment in tight or confined spaces, such as construction sites or urban areas, while maintaining situational awareness and avoiding hazards.

- Performing routine inspections and maintenance checks on equipment to identify and address mechanical issues or safety concerns.

- Following established procedures and safety protocols to prevent accidents, spills, or damage to equipment and property.

- Concrete equipment operators are responsible for operating and maneuvering heavy equipment used in concrete construction, such as concrete trucks, mixers, and batch plants. Their duties include:

- Concrete Surveyors:

- Concrete surveyors specialize in layout and measurement tasks related to concrete construction projects, such as establishing reference points, elevations, and alignments. Their duties include:

- Using surveying instruments such as total stations, levels, and laser scanners to establish horizontal and vertical control points for concrete placement.

- Setting benchmarks, grade stakes, and batter boards to guide formwork installation and ensure proper alignment and elevation.

- Monitoring and verifying the accuracy of concrete placements, dimensions, and profiles using surveying techniques and instruments.

- Providing layout and surveying support to concrete crews throughout the construction process, including as-built surveys and final inspections.

- Concrete surveyors specialize in layout and measurement tasks related to concrete construction projects, such as establishing reference points, elevations, and alignments. Their duties include:

- Concrete Estimators/Project Managers:

- Concrete estimators and project managers oversee the planning, coordination, and execution of concrete construction projects from conception to completion. Their duties include:

- Estimating material quantities, labor costs, and project expenses based on project plans, specifications, and bid documents.

- Developing project schedules, timelines, and resource allocation plans to ensure timely and efficient project delivery.

- Managing project budgets, tracking expenses, and controlling costs to maximize profitability and minimize financial risks.

- Communicating with clients, architects, engineers, and subcontractors to coordinate project activities, resolve issues, and ensure customer satisfaction.

- Concrete estimators and project managers oversee the planning, coordination, and execution of concrete construction projects from conception to completion. Their duties include:

In summary, a Concrete Crew Denton TX comprises a diverse team of skilled professionals with specialized roles

Denton Concrete Crew

1901 Lakeview Blvd, Denton, TX 76208, United States

1-940-461-7177